The surface treatment for the PCB board and their advantage

1. From the color,there are three main colors,golden,silvery and light red.From the price, the golden is the most expensive,the silver is the second, the light red is the cheapest.From the color,we can judge whether manufacturers cut corners.

2. Bare copper board.

Advantage: low cost,flat surface,good soldering(Without oxidization)

Disadvantage:Easy to be affected by acid and humidity,It need to be assembled in 2 hours after removing the seal, because it is easy to oxidize.

If can not be used in 2 layer PCB, because after assembling one side,the other side is oxidized

3. Immersion gold

The Golden is the 10% cost of the PCB board.

Advantage:The gold plating is not easy oxidation,It can be stored for a long time,Flat surface,Suitable for small gap pin and solder joint components.It is the top choice for the PCB with keypads.Reflow soldering can be repeated many times,and it is the basis for the COB bonding.

Disadvantage:Expensive, Poor welding strength

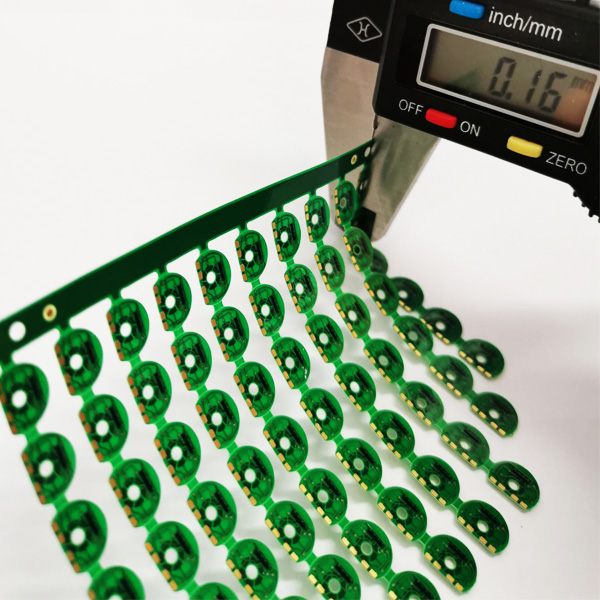

4. HASL

The silvery is HASL PCB.

Advantage:Low cost,good soldering

Disadvantage: Not suitable for small gap pin and solder joint components,It easy to be short circuit for fine pitch.

5. OSP

Advantage:Low cost,cheaper than HASL,OSP has all the advantage of bard copper board, and it can be made surface treatment again when it after expired.

Disadvantage:Easy to be affected by acid and humidity,

The storage time is only 3 months

+86(0755)-23024958

210-215 Compass bulding,Houting,ShaJing town,Baoan District,Shenzhen,China